Pharmaceutical·Biotech Optimizing operation and quality through the Metaverse Factory

페이지 정보

본문

Operational Optimization and Quality Improvement

through the Establishment of a Metaverse Factory

Impix's autonomous manufacturing platform realizes autonomous control of simulations in a virtual environment through the establishment of a metaverse factory.

1. Pain Point

Requirement for quality management system introduction in the pharmaceutical industry

- Validation requirements in the pharmaceutical manufacturing industry

- Process Analytical Technology (PAT)

- Quality by Design (QbD)

2. AI Solution

Autonomous manufacturing solution based on digital twins

3. Construction Goals

Detailed Goals

- The goal is to build a system that enables AI analysis simulation of actual manufacturing processes at the same level as the production site.

- Utilize augmented reality (AR), virtual reality (VR), and extended reality (XR) equipment and metaverse solutions without spatial constraints in the metaverse.

- Expect operational optimization and quality improvement through virtual simulation on ChongKunDang's own metaverse factory.

4. Construction Details

Virtualization

- Virtualization of factory overview, individual buildings, internal structures, facilities, and equipment (total of 15 clean rooms) Synchronization and Animation

- Animation synchronization according to equipment operating status

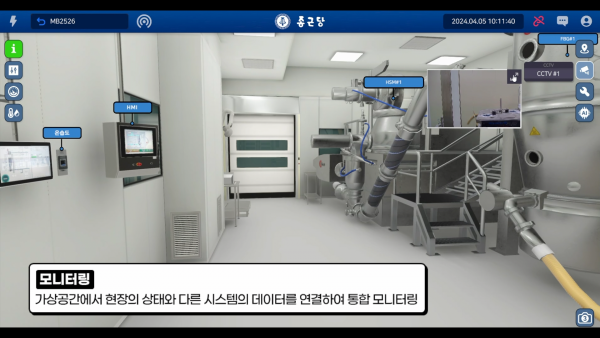

Data integration and monitoring

- Integration and monitoring of CCTV, real-time production status and operating status, changes in key equipment parameters, technical documents such as manuals, and cleanroom environmental information such as temperature, humidity, and differential pressure

Artificial intelligence

- Technology application: quality prediction and derivation of optimal process values, quality simulation of optimal process models

Equipment bidirectional control

- Monitoring and remote control of each equipment's operating status

AR collaboration system

- Real-time video sharing, voice and text chat, and AR Glass Device integration for collaboration between workers in the clean room and external/overseas engineers VR cyber tour

- Experiential cyber tour and promotional content used on the web and VR devices

5. Construction Effects

Productivity Improvement

- Production lead time reduced by 5.12%

AI Performance

- Inspection score prediction accuracy of 88.93% achieved

- Final product quality prediction accuracy of 91.21% achieved

Metaverse Factory Performance

- Data animation synchronization of 16.8ms

- Screen refresh rate of 60fps

- Virtual-real space alignment of 93.33%

- Remote control, command transmission, and processing speed of 20.83ms

Job creation

- new hires, 9

Others

- Two papers and academic journal publications