Nutraceuticals·Cosmetics Cosmetics Manufacturing Process Smart Factory Construction

페이지 정보

본문

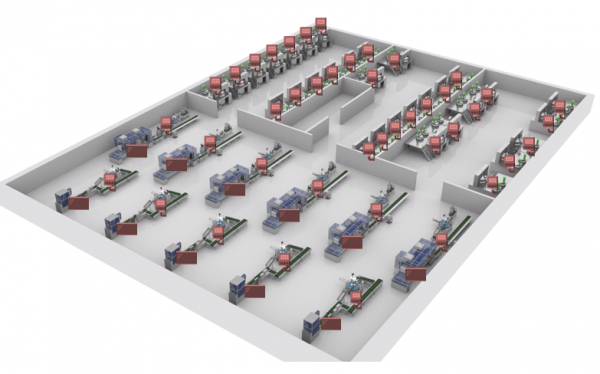

AI-based Cosmetics Manufacturing Process Smart Factory Construction Demonstration

This is Impix's AI solution that predicts and automates cosmetics manufacturing processes and quality.

1. Pain Point

Industrial characteristics

- Need to improve quality and yield to strengthen the global competitiveness of the ODM-centered cosmetics manufacturing industry.

- Difficulties in process management and quality control due to diverse product lines and short product life cycles.

- Delays in identifying causes due to difficulties in tracking all process data when process defects and customer complaints occur.

Data and System Aspects

- Lack of reliability due to manual and partially automated process and quality data management.

- Lack of a quality prediction system based on correlation analysis between process conditions, equipment status, and quality data.

- Lack of an AI-based system capable of real-time collection, visualization, prediction, and analysis of process and equipment data.

Equipment and Infrastructure Aspects

- Lack of a system that can monitor equipment status and quality results in real time and detect quality issues in advance by linking them by process.

- Sunk costs and delivery delays due to defect detection after production completion.

- Need for integrated control and real-time analysis infrastructure for smart factory advancement.

2. AI Solution

Application of AI process and quality prediction and analysis solutions based on A2LAB and One Way Platform

3. Construction Goals

Detailed Objectives

- Establish a process and quality prediction and automation system through AI-based data analysis.

- Improve yield and quality through real-time process monitoring and defect prediction.

- Establish a data-based decision-making system through the construction of a smart HACCP factory.

- Reduce defects through standardization of the entire manufacturing and packaging process and automatic provision of work guidelines.

4. Construction Details

Application of Data Integration Management Technology

- Real-time collection and integrated management of manufacturing process and equipment data, quality data, and ERP/MES data.

- Verification of data consistency and preprocessing, and construction of a learning dataset based on time series labeling.

Application of AI Algorithm Technology

- Application of decision tree and LSTM-based process and quality prediction models.

- Correlation analysis between process data and quality data and derivation of key variables.

- Provision of AI-based real-time defect prediction and work guidance.

Application of Process Quality Prediction and Simulation

- Real-time monitoring and anomaly detection-based quality prediction and process deviation prevention.

- Provision of quality prediction simulation based on digital twins and simulation prior to equipment setup.

- Visualization of AI analysis results on smart factory dashboards and application to work sites.

5. Construction Effects

Reduction in manufacturing process defect rate

- Before introduction: 1.7%

- After introduction: 1.0%

Reduction in raw material waste rate in the packaging process

- Before introduction: 3.4%

- After introduction: 2.0%