Pain Point

Based on facility operation data and production history, we utilize the XGBoost algorithm to build an AI quality classification model that proactively predicts whether a product is good (OK) or bad (NG).

This helps you detect anomalies and ensure process reliability before defects occur.

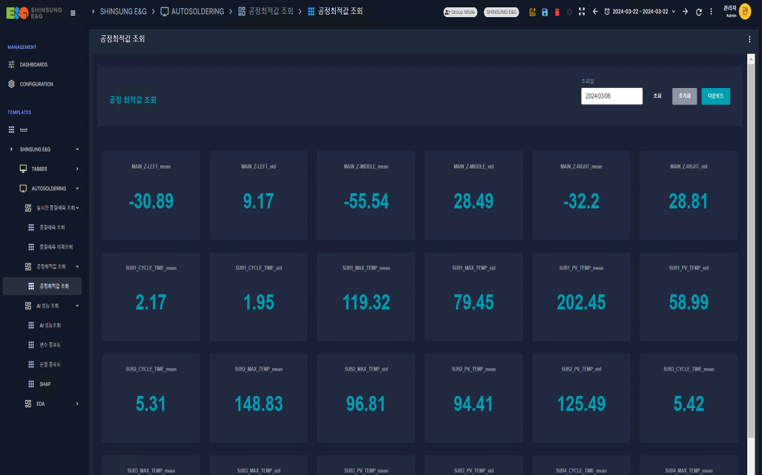

By applying genetic algorithms, AI derives optimal machine operating conditions (temperature, speed, pressure, etc.) to minimize defect rates through iterative simulations.

The AI automatically recommends optimal values even when working conditions change, such as process changes or new workers, contributing to reduced setup time and standardized work.

Visually analyze the key quality influencers determined by AI through Feature Importance, Permutation Importance, and SHAP analysis to clearly understand the basis of the predictions.

This enables data-driven decision-making to interpret the causes of defects in a way that is understandable to operators and to quickly establish improvement measures by cause.

Starting with the construction of a smart factory in 2019,

IMPIX has created best practices optimized for SMEs

through various AX(AI Transformation) projects.