The semiconductor industry is a high-precision manufacturing sector where nanoscale control and yield optimization are critical. To improve nanoscale process precision and yield, AI-based process prediction and optimization technologies are needed to analyze equipment conditions in real time and detect anomalies early.

In order to respond to rapidly changing process conditions, expertise in clean room environmental control, inter-equipment control, and yield optimization algorithms is required.

Required expertise: QbD/PAT regulatory response, GMP-based process knowledge, AI-based quality prediction

We delivered the D² (data lake) solution to Hynix's high-bandwidth memory manufacturing process to implement an AI-based data collection, analysis, and utilization environment. In addition, we installed Non-SECS Boxes on equipment that does not support standard communications to enable integrated data collection from all facilities.

BIG DATA

D2

Supplying data processing software for high-

bandwidth memory manufacturing processes

PHYSICAL AI

Non-SECS Box

Delivery of physical box equipment equipped

with software to connect non-SECS

standard equipment and MES/ERP systems.

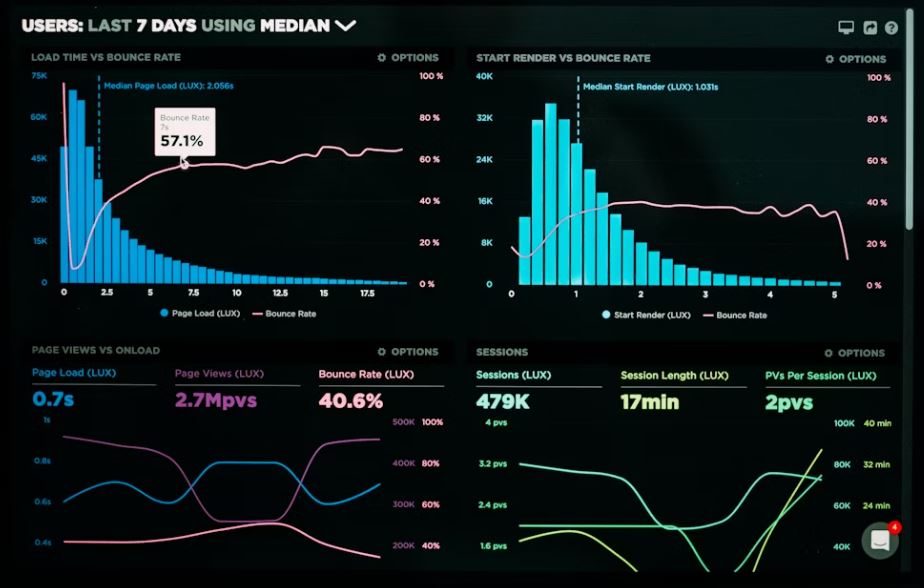

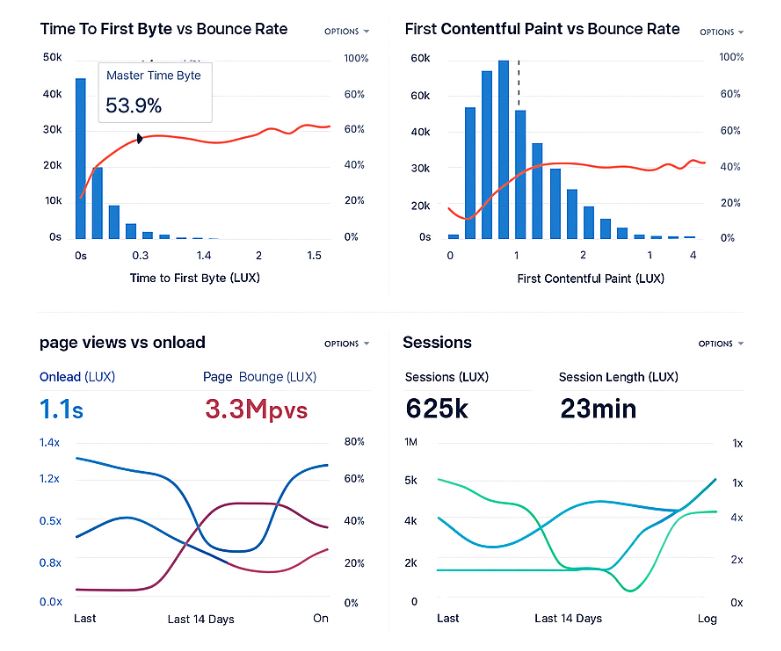

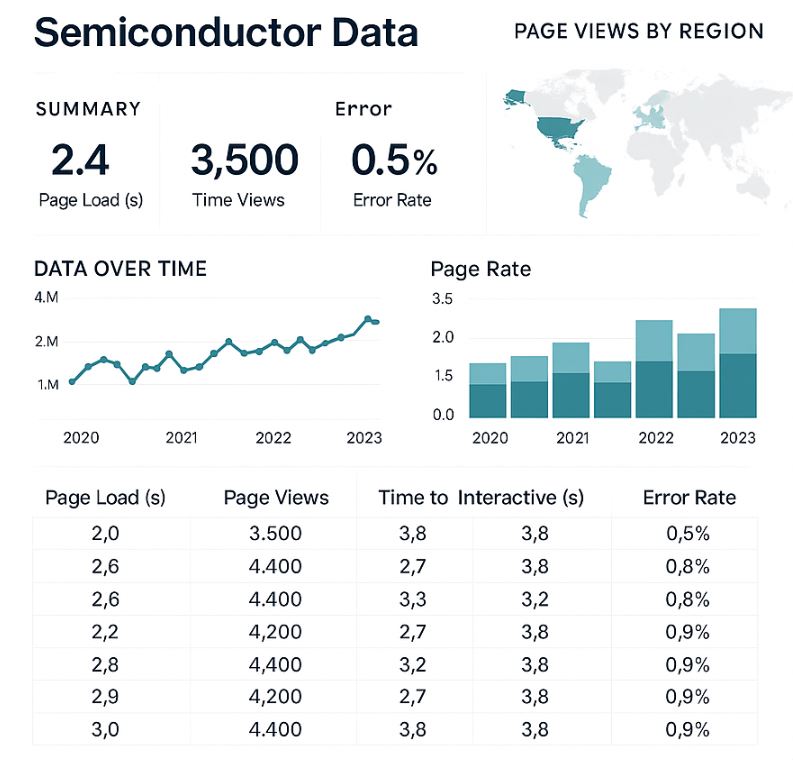

Visualize equipment and sensor status in real time to intuitively understand the overall process situation. Alarms, sensor values, equipment logs are integrated into a web-based dashboard.

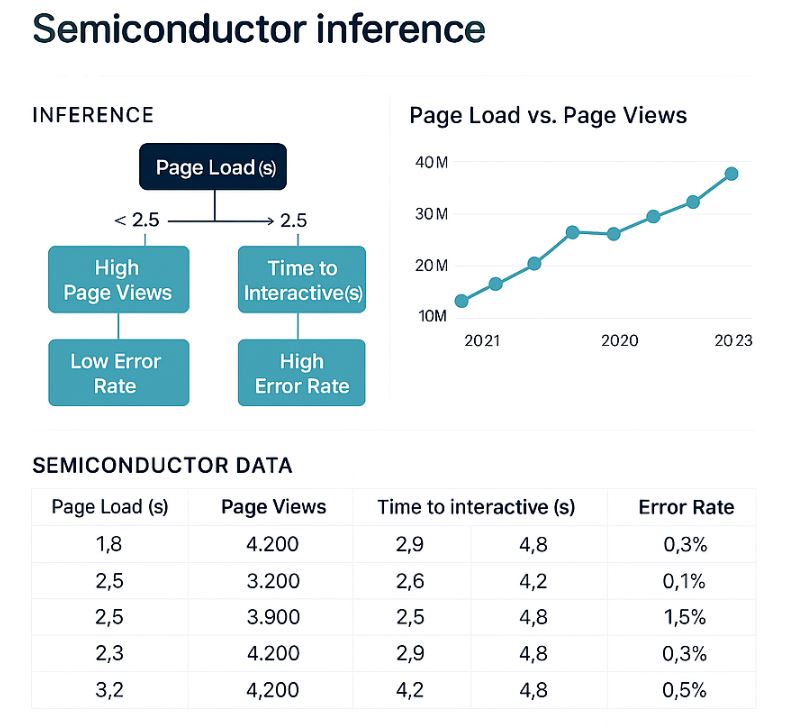

Early identification of process risks, such as anomaly detection and quality trend analysis, based on multidimensional data. Key influencing factors can be identified through AI interpretation-based analysis results, such as SHAP and Permutation.

View AI-predicted quality/facility anomaly results in real time and visually verify them. The most recent inference values and itemized results are automatically linked to the dashboard.

Unifiedly collect, cleanse, and store heterogeneous data from equipment logs, sensors, RFID, CCTV. Automatically configure high-quality datasets for AI learning and data linkage between equipment.

Starting with the construction of a smart factory in 2019,

IMPIX has created best practices optimized for SMEs

through various AX(AI Transformation) projects.